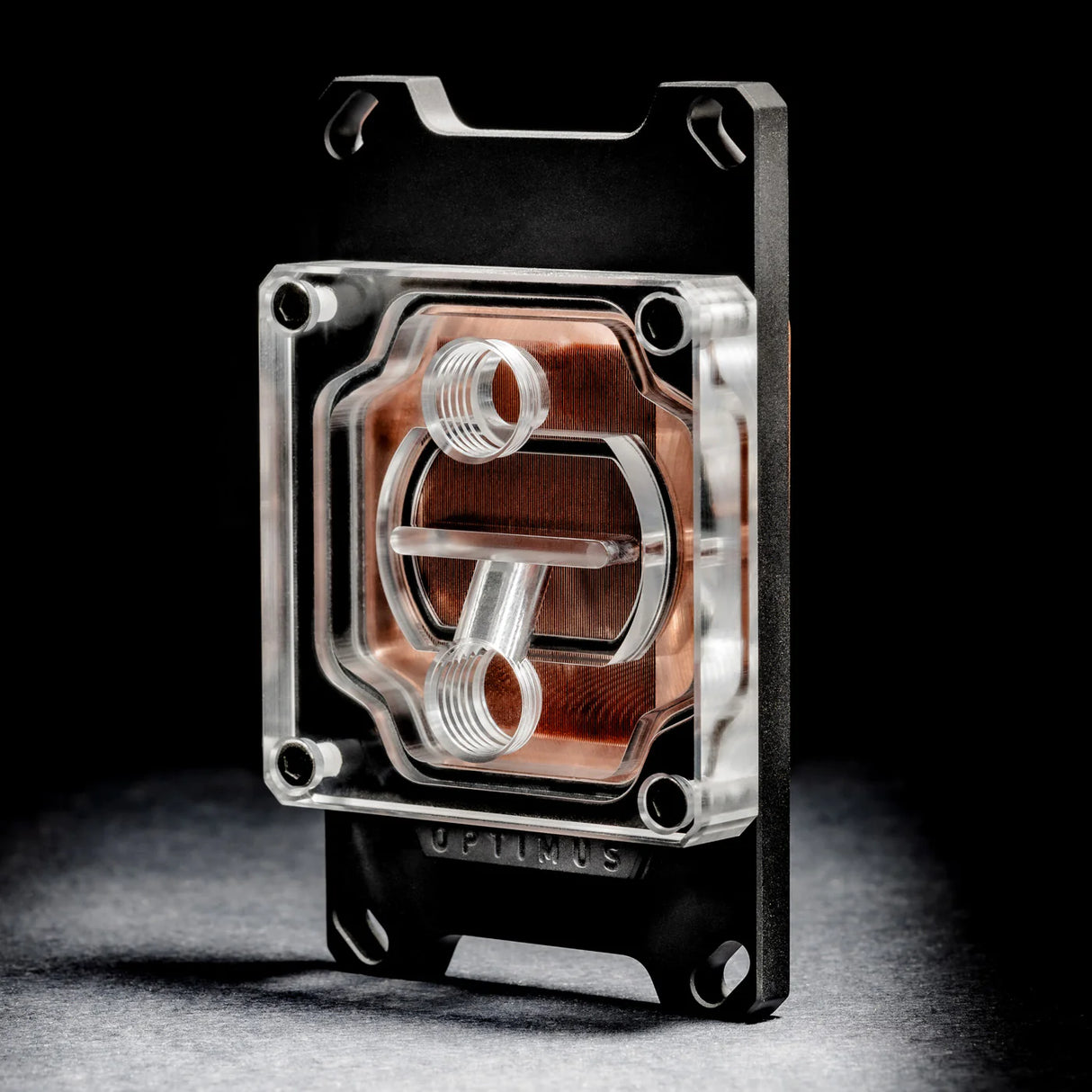

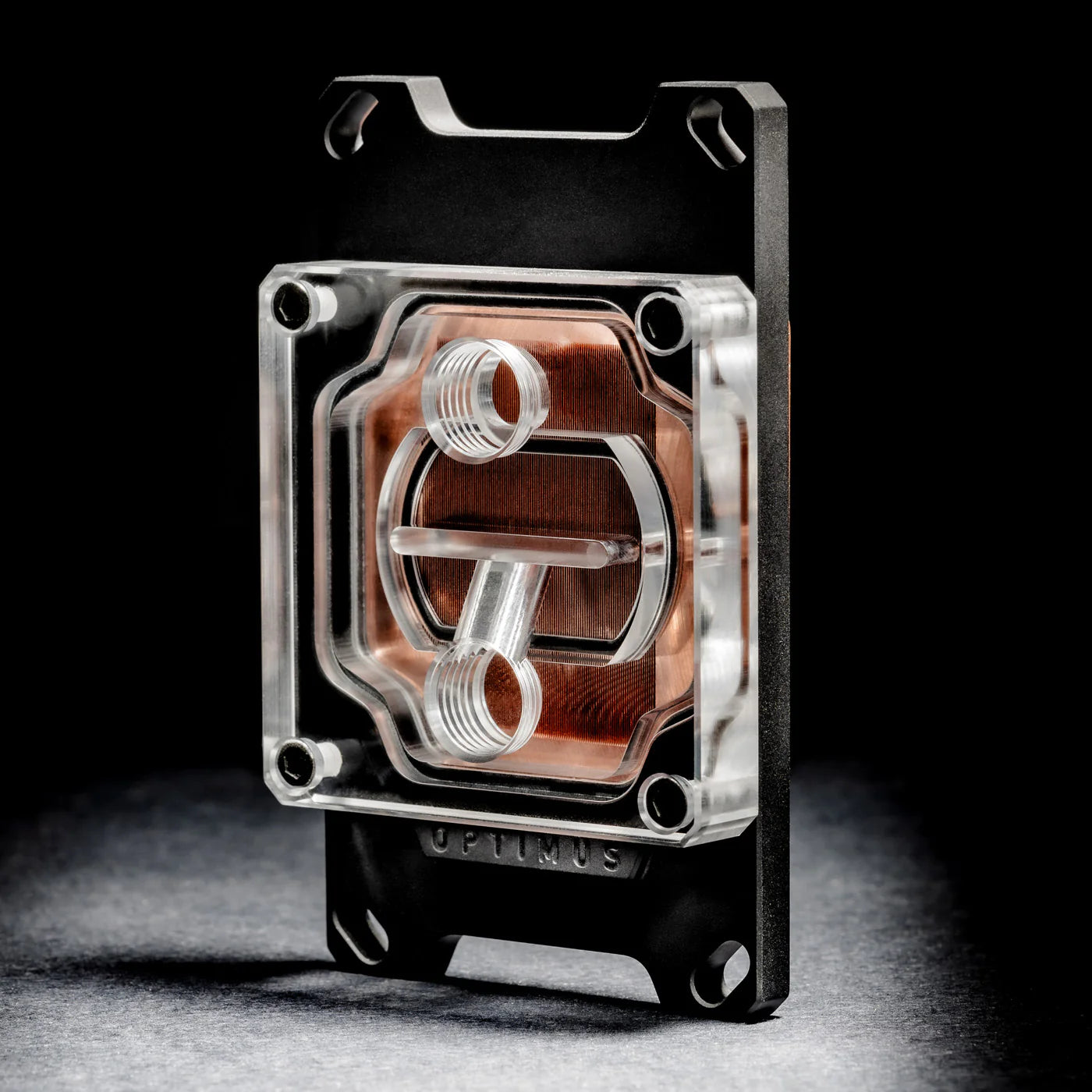

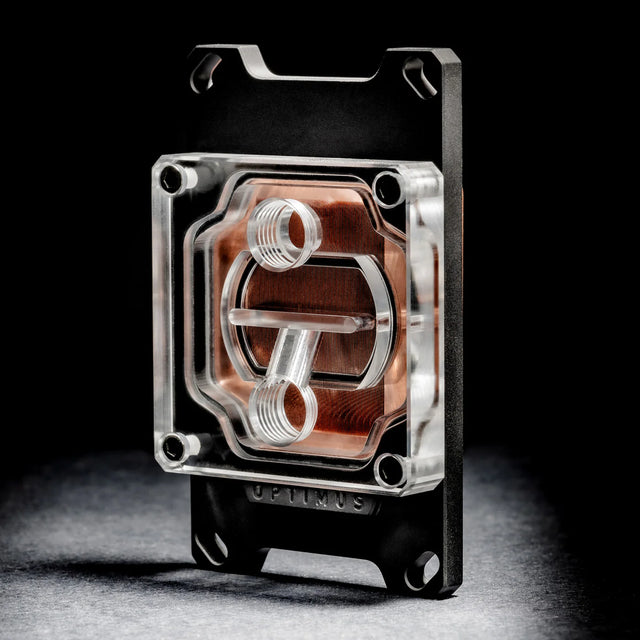

If you're looking for the highest performance Ryzen CPU block, this is it. The Optimus Foundation is designed to provide maximum cooling for all Ryzen CPUs, especially the new Ryzen 7000 series. With up to 16 cores, the new Ryzen uses a new horizontal die layout with larger surface area and even higher thermal requirements. In order to provide max cooling, the Foundation block's fin area covers more than 100% of the dies with a flow-optimized design to wick away large amounts of heat.

PERFORMANCE FIRST MODULAR DESIGN

Made for performance-first, the Foundation block's design allows the liquid flow to match the Ryzen CPU die layout perfectly (see left).

Moreover, the Foundation series is fully modular, meaning the top block and cold plate can be rotated in any direction while keeping the bracket logo upright. That way, you can adjust your inlet/outlet orientation to match your build. While we recommend orienting the flow to match the die layout, you'll still achieve excellent performance in a goofy layout.

A CPU block's performance is only as good as the contact with the CPU. This means mounting pressure and accuracy is paramount for best performance. To achieve this, the Foundation block uses a 1/4" (6.3mm) CNC aluminum mounting plate, rather than stamped steel. This allows high pressure and accuracy when securing the block. Plus, it looks fantastic.

ONLY METAL-TO-METAL SCREW THREADS

All Optimus products are assembled with metal screws into metal threads, never acrylic or acetal threads. Plastic screw threads can easily strip and cause cracks, rendering a block useless. Most acrylic/acetal-threaded blocks can only survive a few assemblies before stripping. By eliminating plastic threads entirely, Optimus blocks are able to be reassembled for years to come. Plus, securing the top block using steel screws into machined aluminum mounting plate means leak-proof pressure.

ELIMINATING CRACKED ACRYLIC

Extruded acrylic with poor machining is the #1 culprit of of cracking in water cooling parts. Extruded acrylic is low cost and easy to make. That’s why extruded is used by nearly every water cooling company.

But extruded acrylic isn’t appropriate for liquid cooling parts. Extruded is prone to stress and spider web fractures from machining and expanding/contracting during temp fluctuations and exposure to liquids. Additionally, injection molded nylon blocks feature similar downsides, including a +/- 10% expansion variation and high fluid retention, all sources of stress. If you’ve ever wondered why ports, screw threads and reservoirs randomly fracture, this is why.

Cast acrylic is far harder with excellent machinability and resistance to cracking. Really, cast acrylic is the only real choice for everything from precision machined parts to giant aquariums. Optimus uses only cast acrylic for every single acrylic component.In fact, our cast acrylic is much stronger than acetal and nearly impossible to break. Feel free to allen wrench your fittings in place, our block won't blink.

DIAMOND VS FLAME POLISHED

Optimus uses only custom designed diamond CNC acrylic bits to achieve high optical quality rather than buffing or flame polishing.Flame polishing, combined with extruded acrylic, causes numerous problems. First, flaming (and vapor) polishing works by melting the outer layer of material to achieve a glass-like appearance. While the results look great, melting causes significant damage to the acrylic structure.With flaming, the acrylic becomes highly prone to stress cracking as well as spider webbing from fluids and temp fluctuations. And flaming has a tendency to turn acrylic yellow.

Moreover, by diamond polishing, we're able to achieve higher clarity in places flaming cannot, like the inside of ports and channels. While this is a far more time consuming and challenging process, we believe the results speak for themselves.

100% CNC MILLED PORTS

Additionally, we only CNC our G1/4” ports, never thread tap. Thread tapping is the industry standard because it’s easy and any budget drill press can do it. Thread tapping works by twisting a threaded drill bit into the material, causing burrs and extreme levels of stress. The resulting thread tapping micro fractures are nearly invisible, until the acrylic meets water, heat and pressure. Then micro turns into macro and cracks appear.

With CNCing (aka thread milling), specialized CNC bits are used to sculpt away the material and make the threads. CNC milling is vastly more accurate and causes far less pressure on the material, but takes much more time and requires high-speed CNC machines. For Optimus, CNC threads are a must.

TRUE BSPP-G1/4" SPEC THREADING

Moreover, with over 50 years making aerospace fittings and parts, we're hyper focused on thread accuracy. All our G 1/4" ports and threads meet BSPP-G specification. This might seem like a small detail, but the accuracy of G 1/4"style fittings and ports on the market varies greatly and can lead to numerous problems like leaks, cracks and cross-threading.

Ultimately, all these steps combined make our acrylic products nearly indestructible. That's why we can offer the industry's only 10 year warranty.

Materials

- TOP PLATE: Cast acrylic from Plexiglas® or black acetal from Röchling

- COLD PLATE: US-sourced premium C110-grade copper, guaranteed ASTM B187 spec

- COLD PLATE FINISH: Raw copper or Pro-XE nickel

- BRACKET: US-sourced machined 6061 aluminum, satin anodized

- O-RINGS: US-made plasticizer-free EPDM o-rings

- SCREWS: 18-8 stainless steel or black oxide over stainless steel mounting screws, stainless steel cold plate screws

- MOUNTING: Optimus-made CNCed posts and thumbscrews

Compatibility

- MOUNTING: AMD AM4 and AM3 sockets. Not compatible with Threadripper TR4

- COOLING: Compatible with all Ryzen series, including 3000 series with 16 cores

- MODULARITY: Modular design for swapping mounting plates, cold plates and tops

In The Box

- 1 x Foundation CPU Block

- 4 x Optimus CNC Mounting Posts

- 4 x Optimus CNC Thumb Screws

- 1 x Thermal paste syringe

FAQ

- COPPER VS NICKEL COLD PLATE? Choose raw copper for highest theoretical performance (depends on overclocking and overall system). Choose nickel for aesthetics and/or liquid metal compatibility

- ACRYLIC VS ACETAL? Our cast acrylic is actually far stronger than acetal, the traditional professional choice. Acetal won't ever crack, but it's soft and will deform with pressure and easily scratch. Our cast acrylic will survive far more abuse than acetal. So for all users, acrylic is recommended, unless you want the black look.

- LIQUID METAL? BARE DIE?Go for it! Remember, liquid metal will etch copper immediately, though some builders like the performance of pure copper. Liquid metal will discolor nickel, but etching will take far longer. In both cases, performance of the cold plate won't be effected.

- THERMAL PASTE? We include US-made Ceramique thermal paste. However, numerous thermal pastes are also excellent. Thermal Grizzly Kryonaut and Arctic MX4 2019 are two of the highest performance we have tested.

- FLOW DIRECTION? Fluid needs to flow in a specific direction -- center of fins and then out. On acrylic blocks, the "in" is connected to the center channel. On acetal blocks, the "out" shows the fins inside, while the fins can't be seen on the "in" port.

- FLUSHING?All Optimus products have already been cleaned before shipping. You'll only need to flush your radiators and non-Optimus products. In fact, heavy system prep chemicals can be detrimental if they remain in small quantities in your loop. This can easily happen with fluid pressurized into o-ring grooves through heating.

- CLEANING? Microfiber is your friend. Dish soap and water is ideal for our products. Always use microfiber glass cloths to prevent any scratches, especially on cold plates. Do not scrub, simply hand rinse. Isopropyl alcohol is not needed and can cause discoloration.

- COPPER OXIDATION? Copper will immediately begin to oxidize (turn brown) when exposed to air. This is normal and expected and won't affect performance unless the oxidization is extreme, like the Statue of Liberty. But you're not leaving your blocks out by the ocean, are you?